In today’s fast-changing manufacturing industry, industrial robots and robotic manufacturing have become key drivers of innovation and efficiency. The introduction of robotics into manufacturing has revolutionized the process. It has a myriad of advantages to companies seeking to improve productivity as well as quality and competitiveness. Manufacturing robots are expected to play a larger influence on the future of manufacturing as demand for solutions that automate production increases.

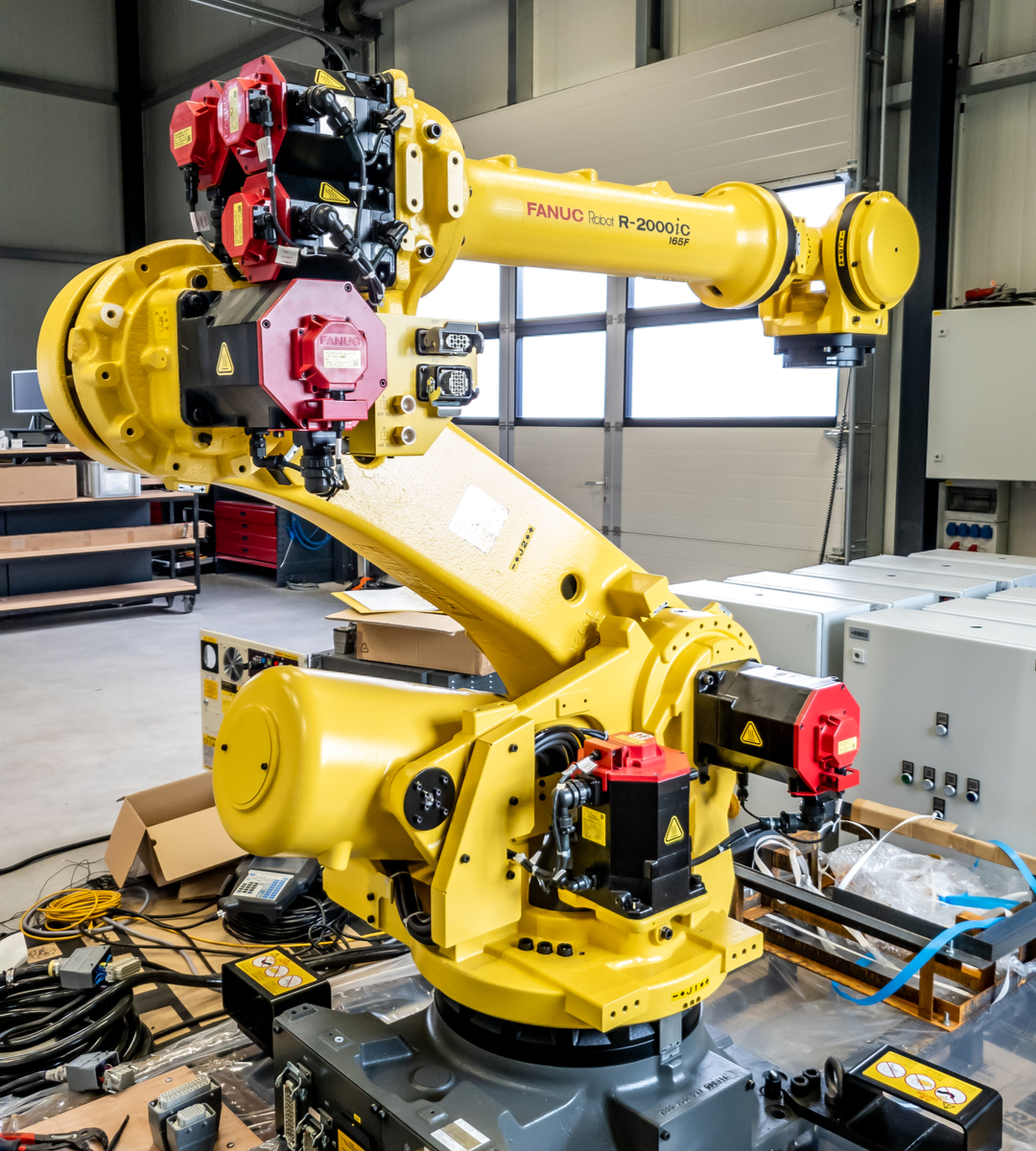

Industrial robots are also called manufacturing robots. They are specially designed machines that are able to perform multiple functions in the industrial setting. They can be used for welding, painting, assembly, packaging and picking, and other things. Industrial robotics is the study and application of robotics. It focuses on increasing efficiency and precision during manufacturing processes.

Automated Solutions Australia is one of the companies on the forefront. They specialize in industrial robots that provide flexible automation for manufacturing clients. ASA robotics for manufacturing in industrial settings aim to assist clients gain an edge in the market by increasing the quality of their products and increasing productivity. With a strong commitment to best practices ASA’s industrial robotics are sought after by businesses worldwide in numerous industries, including automotive, electronics pharmaceuticals, among others.

The benefits of implementing industrial robots in manufacturing are multifaceted. The main benefit is improvement in productivity and efficiency. Industrial robots are capable of performing repetitive tasks with accuracy and consistency, which results in increased output and shorter cycles. This improves overall efficiency, but also allows companies to meet growing consumer requirements with ease.

Furthermore, industrial robots help improve the quality control of manufacturing processes. These robots reduce the margin of error because they perform tasks accurately and reliably and resulting in higher quality goods. It also increases customer satisfaction and improves the image of a business to provide high-quality products.

Industrial robots aren’t only efficient and high-quality, they also help you save money. The initial price of making robots could be high but the savings over time are huge. Through streamlining processes in production and reducing the need to use manual labor, businesses are able to reduce their operational expenses and earn a quick ROI. Additionally, industrial robots can run 24/7, maximising the use of resources while driving down per-unit production costs.

The impact of industrial robots on working environment is a further compelling advantage. They are engineered to produce low noise levels which create a more peaceful and more comfortable work environment for workers. Additionally, their precision and speed help create a safer workplace as they reduce the risk of injuries and accidents that are associated with manual labor.

The integration of industrial robots also plays a crucial role in the creation of jobs and the future of work. Although there are concerns about automation displacing human workers However, the reality is industrial robots open up new avenues to work. This includes roles in the field of robotic programming maintenance, oversight, and control, as well as the creation of new technology to assist in manufacturing robots.

As businesses in various industries continue to profit from the advantages of industrial robots as the manufacturing sector continues to adopt the technology, it is revolutionizing the way that manufacturing is conducted. Industrial robotics have the potential to improve efficiency, effectiveness and quality. It is changing the industry of manufacturing and set new standards of excellence.

In the end, the rise of manufacturing robots and industrial robotics has created a paradigm shift in the manufacturing sector. The fusion of these technologies allows businesses to achieve new levels in effectiveness and precision, as well as competitiveness and efficiency. As the use of automation continues to increase, industrial robots are able to play a significant role in shaping the future of manufacturing, driving innovation and propelling companies to success in the world market.